The modern residential bathroom is trending toward a spa atmosphere containing a single or a combination of water features such as bathtubs, showers, hot tubs and steam rooms, each contributing to creating wet and high-moisture environments. Other water exposure concerns include potential overflows or backups from sinks, tubs or commodes, coupled with the occasional plumbing leaks. The power of water and moisture in vapor form is immense, with the potential to do great harm to such construction materials as wood subfloors, wall framing and wallboards in an unprotected tiled bathroom. Of equal importance is protecting the areas adjacent to and below the bathroom from the ill effects of leaks or vapor condensation, increasing concerns related to mold- and mildew-friendly environments.

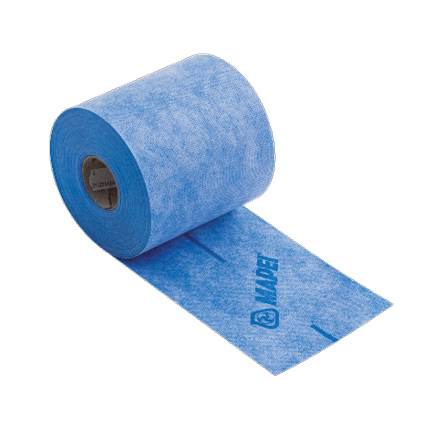

MAPEI’s Mapeguard WP waterproofing membrane systems are uniquely engineered to deliver waterproofing, crack-isolation and vapor-control solutions, addressing the demands of wet and high-moisture environments encountered in today’s ceramic tile and stone installations. From the installer’s perspective, Mapeguard WP 200 waterproofing sheet membrane with its desired feel and pliability is application-friendly, as an added benefit to the high performance standards attained in strength and dimensional stability. With its low perm rating, the system is approved for residential and commercial steam rooms, where the demands for vapor protection are critical. In addition to Mapeguard WP 200 sheet membrane, the components of the Mapeguard WP waterproofing membrane system can include Mapeguard WP ST waterproofing sealing tape, Mapeguard PIC pre-formed inside corners, Mapeguard POC pre-formed outside corners, Mapeguard PC pre-formed pipe collars and Mapeguard VC pre-formed valve collars.

When these system components are used with a MAPEI mortar and grout, either a 10-year, 25-year or lifetime warranty will apply, depending on the products selected. The warranty term is based on product classifications according to industry standards and approvals. Mapeguard WP waterproofing membrane systems provide customers, contractors, architects and owners with single-source solutions from MAPEI, supported with its Best-Backed warranty program.

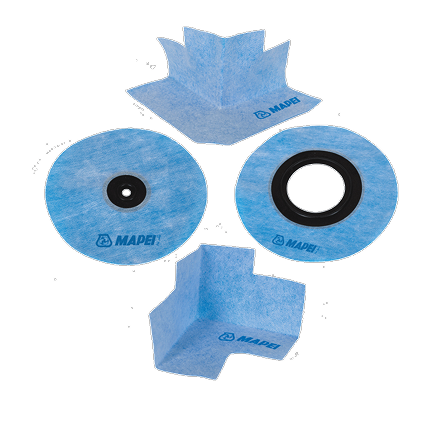

Components of Mapeguard WP waterproofing membrane systems can be purchased individually. Additionally, some components are offered collectively as the Mapeguard Combo Pack.

The Mapeguard Combo Pack consists of inside corners, outside corners, pipe collar and valve collar components packaged together in a kit. The installation corners and collar kit is a convenient, fast and easy way to seal around curbs, inside corners, outside corners, pipes, shower heads and shower mixing valves in wet areas, providing waterproofing and vapor-management protection when installing Mapeguard WP 200 waterproofing membrane for ceramic tile and stone.

Description

Mapeguard WP 200 is a thin, flexible polyethylene sheet membrane with a nonwoven, polypropylene fabric on both sides, for both waterproofing and crack isolation in interior/exterior residential and commercial applications. The laminated fabric webbing is designed to anchor the waterproof membrane to the substrate and tiles to the membrane using the bonded thin-set method with recommended, polymer modified mortars. Mapeguard WP 200’s low perm rating performance is ideal for vapor protection in showers, bathroom floors and walls and other wet areas, as well as suitable for steam rooms in residential and commercial environments.

Mapeguard WP 200 is a thin, flexible polyethylene sheet membrane with a nonwoven, polypropylene fabric on both sides, for both waterproofing and crack isolation in interior/exterior residential and commercial applications. The laminated fabric webbing is designed to anchor the waterproof membrane to the substrate and tiles to the membrane using the bonded thin-set method with recommended, polymer modified mortars. Mapeguard WP 200’s low perm rating performance is ideal for vapor protection in showers, bathroom floors and walls and other wet areas, as well as suitable for steam rooms in residential and commercial environments.

Note: On occasion, dimensionally weak natural-stone tile that normally would not be categorized as moisture-sensitive (such as travertine, limestone, marble and agglomerates) can exhibit doming, cupping or curling when large-and-heavy tile mortars (previously called “medium-bed mortars”) are used over impervious sheet membranes such as Mapeguard WP 200 underlayment membrane. For this reason, areas requiring more than 3/8" (10 mm) thin-set mortar buildup require the use of a self-leveling underlayment or cured mud-bed application before installation of Mapeguard WP 200. When installing natural stone, always do a mockup area of the proposed installation and allow materials to reach a full cure to ensure the desired effect. For details on these methods or materials, contact MAPEI’s Technical Services Department before installation or design.

Consult MAPEI’s Technical Services Department for installation recommendations regarding substrates and conditions not listed.

See the “Surface preparation requirements” reference guide.

All concrete substrates must be structurally sound, stable, dry, clean, and free of any substance or condition that may reduce or prevent proper adhesion. Concrete must be cured sufficiently to support tile installation traffic as determined by the design professional, construction manager or general contractor. The surface should be free of voids, sharp protrusions, loose aggregate, cement laitance, concrete sealers and curing compounds. All exterior applications must be properly and uniformly sloped.

Refer to the “Tiling over gypsum” technical bulletin.

1. Inspect the subfloor before installing Mapeguard WP 200 underlayment membrane to ensure that the substrate is acceptable for tile or stone installation.

2. Snap chalk lines on the substrate and dry-fit Mapeguard WP 200, cutting the membrane to the required size for the installation. Allow for upturns and 2" (5 cm) overlaps as desired, or use Mapeguard WP ST instead of upturns and edge laps.

3. Mix a suitable MAPEI mortar for the substrate to a consistency on the high end of the recommended water range, in order to hold a notched ridge while allowing for wetting out of the fabric layer backing of the membrane.

4. Refer to the Technical Data Sheet for Mapeguard WP 200 for complete installation details pertaining to membrane, sealing tape, inside corners, outside corners, pipe collars and valve collars.

Use a MAPEI polymer-modified mortar meeting ANSI A118.11 or ANSI A118.15 standard or classified as ISO 13007 C2E, C2F or better for installing Mapeguard WP 200 in the applicable interior installation over approved wood substrates.

For ceramic, porcelain and stone tile: In accordance with the TCNA Handbook for Ceramic Tile Installation and with porcelain tile manufacturers, use a MAPEI polymer-modified mortar suitable for the tile being installed. The mortar should meet the ANSI A118.4, ANSI A118.11 or ANSI A118.15 standard, or be classified as ISO 13007 C2E, C2F or better.

Tiles may be grouted once the mortar has cured enough to allow light traffic, which will depend upon the mortar used, tile size, tile type and jobsite conditions. Select an appropriate MAPEI cement, ready-to-use or epoxy grout. For exterior installations, use MAPEI’s Ultracolor Plus FA rapid-setting grout. Allow for longer drying time before grouting when installing large-format tiles (that is, tiles greater than 15" [38 cm] on one or more sides).

Flood-testing is recommended before the finished flooring is installed, even if not required. Allow the system of Mapeguard WP 200, seams and connections to cure at least 24 hours at 73°F (23°C) and 50% relative humidity. Actual curing time depends on air and substrate temperatures, substrate porosity and humidity. Expect shorter drying times in warmer conditions, and longer drying times in cooler conditions.

| Laboratory Tests | Results |

|---|---|

| ASTM C627 Service Rating (Robinson) | |

| 16" (41 cm) o.c., wood substrate | Heavy |

| Concrete slab | Extra Heavy |

| Shelf life | 2 years when stored in original, unopened packaging at 73°F (23°C) and 50% RH |

| Physical state | Polyethylene sheet membrane with non-woven polypropylene fabric on both sides |

| Thickness | 0.02" (0.44 to 0.48 mm), nominally 17 to 19 mils |

| Color | Blue |

| Storage and performance temperature range | -4°F to 122°F (-20°C to 50°C) |

| Property | Test Results |

|---|---|

| System performance – ANSI A118.10 | Pass |

| Fungus and microorganism resistance – ANSI A118.10 | No mold growth |

| Seam strength – ANSI A118.10 and ASTM D751 | 23 lbs./in. (0.02kgf/mm2) |

| Breaking strength – ANSI A118.10 and ASTM D751 | |

| Transverse | 1,365.6 psi (9.42 MPa) |

| Longitudinal | 2,003.2 psi (13.8 MPa) |

| Dimensional stability – ANSI A118.10 and ASTM D1240 | < 0.7% |

| Waterproofness – ANSI A118.10 and ASTM D4068 | Pass |

| Shear strength to ceramic tile and cement mortar – ANSI A118.10 and ASTM C482 | > 50 psi (0.34 MPa) |

| Water vapor transmission – ASTM E96 (Method E) | 0.22 (grains/h·ft2) |

| Permeance – ASTM E96 (Method E) | 0.12 perms |

| Shear strength – ASTM C482 | |

| 7 days, dry | 136.6 psi (0.94 MPa) |

| 7 days, water immersion | 120.4 psi (0.83 MPa) |

| 4 weeks | 112.8 psi (0.78 MPa) |

| 12 weeks | 132.5 psi (0.91 MPa) |

| 100 days, water immersion | 142.4 psi (0.98 MPa) |

| Crack isolation – ANSI A118.12 | High performance > 1/8" (3 mm) |

| Size | Coverage |

|---|---|

| Roll: 39.4" x 16.4' (1 m x 5 m) | 53.8 sq. ft. (5 m²) |

| Roll: 39.4" x 32.8' (1 m x 10 m) | 108 sq. ft. (10 m²) |

| Roll: 39.4" x 98.4' (1 m x 30 m) | 323 sq. ft. (30 m²) |

| Roll: 6' x 50' (1.83 m x 15.2 m) | 300 sq. ft. (27.9 m²) |

Description

Mapeguard WP ST is a fast and easy way to cover seams and wall upturns to provide waterproofing and vapor management protection when installing Mapeguard WP 200 waterproofing sheet membrane for ceramic tile and stone.

Mapeguard WP ST is a fast and easy way to cover seams and wall upturns to provide waterproofing and vapor management protection when installing Mapeguard WP 200 waterproofing sheet membrane for ceramic tile and stone.

Features and Benefits

| Type of material | Polyethylene sheet membrane with non-woven polypropylene fabric on both sides |

| Physical state | 0.01" (0.30 to 0.40 mm), nominally 30 to 40 mils |

| Tape color | Blue |

| Storage and performance temperature range | -4°F to 122°F (-20°C to 50°C) |

| Shelf life | 2 years when stored in a dry area in original shipping package at 73°F (23°C) and 50% relative humidity |

| Size | Coverage | Product Code |

|---|---|---|

| Roll: 4.7" x 16.4' (12 cm x 5 m) | 16.4 lineal ft. (5 m) per roll | 2856405 (10 units per case) |

| Roll: 4.7" x 32.8' (12 cm x 10 m) | 32.8 lineal ft. (10 m) per roll | 2856410 (10 units per case) |

| Roll: 4.7" x 98.4' (12 cm x 30 m) | 98.4 lineal ft. (30 m) per roll | 2856430 (10 units per case) |

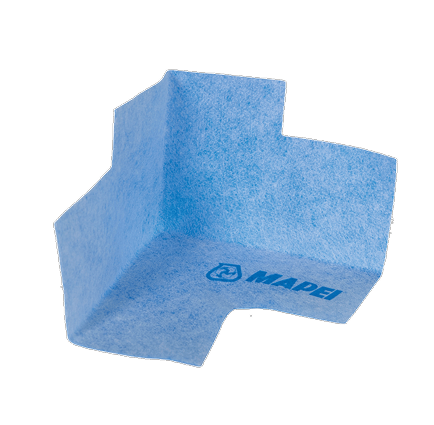

Description

Mapeguard PIC is a thin, flexible, alkali-resistant, polyethylene membrane coated on both sides with a nonwoven polypropylene fabric. It offers a fast and easy way to seal inside corners in wet areas where walls and floors meet, providing waterproofing and vapor management protection when combined with Mapeguard WP 200 waterproofing membrane for ceramic tile and stone.

Mapeguard PIC is a thin, flexible, alkali-resistant, polyethylene membrane coated on both sides with a nonwoven polypropylene fabric. It offers a fast and easy way to seal inside corners in wet areas where walls and floors meet, providing waterproofing and vapor management protection when combined with Mapeguard WP 200 waterproofing membrane for ceramic tile and stone.

Features and Benefits

| Shelf life | 2 years when stored in a dry area in original shipping package at 73°F (23°C) and 50% relative humidity |

| Type of material | Polyethylene sheet membrane with non-woven polypropylene fabric on both sides |

| Material thickness | 0.03" (0.45 to 0.65 mm), nominal |

| Membrane color | Blue |

| Storage and performance temperature range | -4°F to 122°F (-20°C to 50°C) |

| Size | Coverage | Product Code |

|---|---|---|

| 4-5/16" x 4-5/16" x 3-1/2" (11 x 11 x 9 cm), nominal | 2 per package with 10 packages per box | 2858102 (20 units per case) |

| 4-5/16" x 4-5/16" x 3-1/2" (11 x 11 x 9 cm), nominal | Bulk box | 2858101 (25 units per case) |

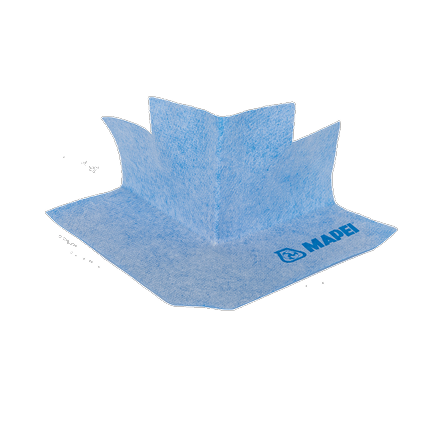

Description

Mapeguard POC is a thin, flexible, alkali-resistant, polyethylene membrane coated on both sides with a nonwoven polypropylene fabric. It offers a fast and easy way to seal outside corners, curbs or return walls in wet areas where walls/curbs and floors meet, providing waterproofing and vapor management protection when combined with Mapeguard WP 200 waterproofing membrane for ceramic tile and stone.

Mapeguard POC is a thin, flexible, alkali-resistant, polyethylene membrane coated on both sides with a nonwoven polypropylene fabric. It offers a fast and easy way to seal outside corners, curbs or return walls in wet areas where walls/curbs and floors meet, providing waterproofing and vapor management protection when combined with Mapeguard WP 200 waterproofing membrane for ceramic tile and stone.

Features and Benefits

| Shelf life | 2 years when stored in a dry area in original shipping package at 73°F (23°C) and 50% relative humidity |

| Type of material | Polyethylene sheet membrane with non-woven polypropylene fabric on both sides |

| Material thickness | 0.03" (0.45 to 0.65 mm), nominal |

| Membrane color | Blue |

| Storage and performance temperature range | -4°F to 122°F (-20°C to 50°C) |

| Size | Unit | Product Code |

|---|---|---|

| 4-5/16" x 4-5/16" x 3-1/2" (11 x 11 x 9 cm), nominal | 2 per package with 10 packages per box | 2858202 (20 units per case) |

| 4-5/16" x 4-5/16" x 3-1/2" (11 x 11 x 9 cm), nominal | Bulk box | 2858201 (25 units per case) |

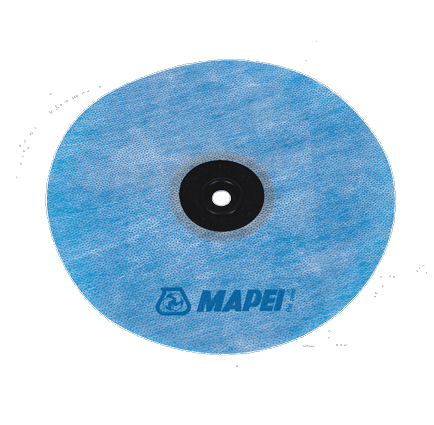

Description

Mapeguard PC is a thin, flexible, alkali-resistant, polyethylene membrane coated on both sides with a nonwoven polypropylene fabric. It offers a fast and easy way to seal outside corners, curbs or return walls in wet areas where walls/curbs and floors meet, providing waterproofing and vapor management protection when combined with Mapeguard WP 200 waterproofing membrane for ceramic tile and stone.

Mapeguard PC is a thin, flexible, alkali-resistant, polyethylene membrane coated on both sides with a nonwoven polypropylene fabric. It offers a fast and easy way to seal outside corners, curbs or return walls in wet areas where walls/curbs and floors meet, providing waterproofing and vapor management protection when combined with Mapeguard WP 200 waterproofing membrane for ceramic tile and stone.

Features and Benefits

| Shelf life | 2 years when stored in a dry area in original shipping package at 73°F (23°C) and 50% relative humidity |

| Type of material | Polyethylene sheet membrane with non-woven polypropylene fabric on both sides |

| Material thickness | 0.02" (0.35 to 0.45 mm), nominal |

| Membrane color | Blue |

| Storage and performance temperature range | -4°F to 122°F (-20°C to 50°C) |

| Size | Unit | Product Code |

|---|---|---|

| Round 7.1" (18 cm), nominal | 1 per package with 10 packages per box | 2854101 (10 units per case) |

| Round 7.1" (18 cm), nominal | Bulk box | 2854125 (25 units per case) |

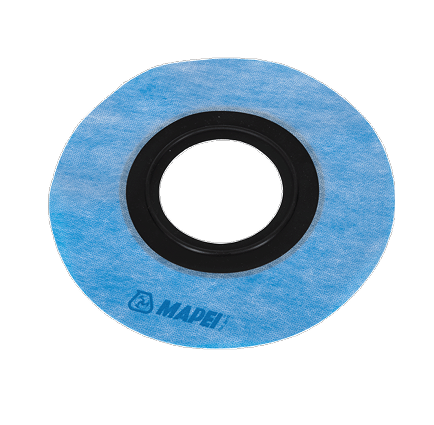

Description

Mapeguard VC is a thin, flexible, alkali-resistant, polyethylene membrane coated on both sides with a nonwoven polypropylene fabric engineered with a stretchable rubber center. It provides a fast and easy way to seal around shower mixing valves in wet areas, providing waterproofing and vapor management protection when combined with Mapeguard WP 200 waterproofing membrane for ceramic tile and stone.

Mapeguard VC is a thin, flexible, alkali-resistant, polyethylene membrane coated on both sides with a nonwoven polypropylene fabric engineered with a stretchable rubber center. It provides a fast and easy way to seal around shower mixing valves in wet areas, providing waterproofing and vapor management protection when combined with Mapeguard WP 200 waterproofing membrane for ceramic tile and stone.

Features and Benefits

| Shelf life | 2 years when stored in a dry area in original shipping package at 73°F (23°C) and 50% relative humidity |

| Type of material | Polyethylene sheet membrane with non-woven polypropylene fabric on both sides |

| Material thickness | 0.02" (0.35 to 0.45 mm), nominal |

| Membrane color | Blue |

| Storage and performance temperature range | -4°F to 122°F (-20°C to 50°C) |

| Size | Unit | Product Code |

|---|---|---|

| Round 9.84" (25 cm), nominal | 1 per package with 10 packages per box | 2856601 (10 units per case) |

| Round 9.84" (28 cm), nominal | Bulk box | 2856625 (25 units per case) |

Description

Mapeguard Combo Pack consists of inside corners, outside corners, pipe collar and valve collar components packaged together in a kit. This kit offers a convenient, fast and easy way to seal around curbs, inside corners, outside corners, pipes, shower heads and shower mixing valves in wet areas to provide waterproofing and vapor management protection, when combined with Mapeguard WP 200 waterproofing membrane for ceramic tiles and stone.

Mapeguard Combo Pack consists of inside corners, outside corners, pipe collar and valve collar components packaged together in a kit. This kit offers a convenient, fast and easy way to seal around curbs, inside corners, outside corners, pipes, shower heads and shower mixing valves in wet areas to provide waterproofing and vapor management protection, when combined with Mapeguard WP 200 waterproofing membrane for ceramic tiles and stone.

Features and Benefits

| Size | Product Code |

|---|---|

| Box containing 4 Mapeguard PIC inside corners, 4 Mapeguard POC outside corners, 1 Mapeguard PC pipe collar and 1 Mapeguard VC valve collar | 2856301 |

When a Mapeguard WP waterproofing membrane system is used with a MAPEI mortar and grout, either a 10-year, 25-year or lifetime warranty will apply, depending on the selection of the products used. The term of the warranty is based on product classifications according to industry standards and approvals.

When a Mapeguard WP waterproofing membrane system is used with a MAPEI mortar and grout, either a 10-year, 25-year or lifetime warranty will apply, depending on the selection of the products used. The term of the warranty is based on product classifications according to industry standards and approvals.

The combination of Ultraflex LFT modified large-and-heavy-tile mortar and Ultracolor Plus FA grout with a Mapeguard WP waterproofing membrane system is covered by a 25-year system limited warranty. Materials and labor are included in this warranty.

For Additional Information on Mapeguard WP waterproofing membrane system videos and technical literature, visit www.mapei.com.

Comments

Load more comments