Mapecrete System is a proven technology by MAPEI for producing shrinkage compensated concrete, where a high degree of dimensional stability is required to prevent shrinkage cracks in concrete structures.

Mapecrete System is a proven technology by MAPEI for producing shrinkage compensated concrete, where a high degree of dimensional stability is required to prevent shrinkage cracks in concrete structures.

Mapecrete System is based on the principle that concrete shrinkage may be restrained by a structural reinforcement system. MAPEI has a complete range of products able to control the chemical reactions and physical processes within concrete over time. By selecting the right quantity of suitable admixtures, the amount of shrinkage in concrete may be calculated and, therefore, controlled.

Mapecrete System is applied by combining a blend of three different admixtures within the concrete: A mid-range water reducer specifically developed for concrete slabs, a shrinkage-compensating agent and a shrinkage-reducing admixture. The effect of this system is guaranteed by the synergistic effect of the three products combined with the use of a synthetic fiber.

There are no particular drawbacks with Mapecrete System, and it may be used for any type of structure. The system, which guarantees a reduction in the level of concrete surface shrinkage cracks (sometimes called plastic shrinkage cracking), reduces the amount of weak points in the concrete and increases its durability, thereby extending the service life of the structure.

Mapecrete System has been successfully used in various construction projects, including in areas with structural requirements. These are some of the most common areas of use:

Mapecrete System has been successfully used in various construction projects, including in areas with structural requirements. These are some of the most common areas of use:

With industrial floors, one of the main causes of deterioration is the development of hydraulic shrinkage cracks, rather than plastic shrinkage cracks. This phenomenon is controlled by inserting joints in appropriate positions. Mapecrete System allows the number of contraction joints to be reduced and, in certain cases, to be completely eliminated.

Mapecrete technology is also successfully used for concrete floor slabs on bridges. With this particular type of application, because the structure will always be exposed to temperature variations wherever they are located, expansion joints are always required.

Mapecrete System is also often used for repair work on bridge piles, where it is important that the variation in volume of the support concrete is the same as that of the concrete used to carry out the repair work.

The mixture proportions of concrete are extremely important in order to correctly use Mapecrete System and have good results. The factors that need to be taken into consideration for concrete mixtures are maximum water content, the type and amount of cement used, the water/cement ratio and the type of aggregate used. These elements must never be overlooked when designing a concrete mix with the three components of Mapecrete System:

The mixture proportions of concrete are extremely important in order to correctly use Mapecrete System and have good results. The factors that need to be taken into consideration for concrete mixtures are maximum water content, the type and amount of cement used, the water/cement ratio and the type of aggregate used. These elements must never be overlooked when designing a concrete mix with the three components of Mapecrete System:

Dynamon system is a range of modified acrylic-based admixtures made by MAPEI. Dynamon system facilitates the hydration process, allowing the amount of mixing water to be considerably reduced and extends workability, depending on each site’s particular requirements. Within this product group, Dynamon Easy 75 was specifically developed to provide an exceptional air-content stability even when the concrete is re-tempered on-site. Moreover, its formulation dramatically facilitates the finishing operations.

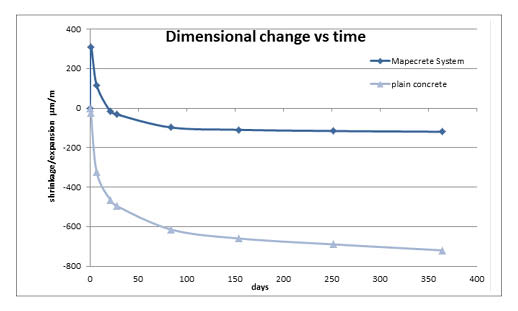

Mapecure SRA 27 [NA] is a liquid admixture supplied by MAPEI that is used to reduce drying shrinkage. Laboratory tests have demonstrated that using SRA admixtures reduces drying shrinkage after 28 days up to 50%. Mapecrete System uses the synergic effect of the three single components to increase expansion during the first phase and reduce the effect of shrinkage during the second phase, when the level of relative humidity is that of the surrounding environment. What is the shrinkage of concrete?

The above chart illustrates the dimensional change measured in the laboratory on concrete specimens of a reference mix, and then on the same mix incorporating Mapecrete System.

One of the conditions for Mapecrete System to work effectively is that the concrete must always be strengthened using synthetic fibers, such as with Mapefibre ST42 or Mapefibre ST55, or with a single or double layer of metallic strengthening mesh – so that the minimum percentage, in terms of ratio between section of rebars and section of concrete, cannot be lower than 0.15%. The expansion induced by the admixtures is restrained by the reinforcement to generate a sort of pre-stressed condition that gradually decreases as drying shrinkage advances. The reduction in the level of internal tensile stresses eliminates the risk of cracking.

The remaining drying shrinkage is offset by Expancrete [NA], a powder admixture slowly reacting with the concrete mixing water to ensure the overall volumetric stability.

The curing of concrete containing Mapecrete System must be always performed and preferably extended to 10 to 14 days after the concrete is poured. Performing the curing process correctly is crucial to ensure maximum performance of Mapecrete System.

The curing of concrete containing Mapecrete System must be always performed and preferably extended to 10 to 14 days after the concrete is poured. Performing the curing process correctly is crucial to ensure maximum performance of Mapecrete System.

![Mapecure SRA 27 [NA]](https://cdnmedia.mapei.com/images/librariesprovider65/products-images/4_mapecure-sra-27-appl_cc7abd3efb12484a9ca14091932ea760.tmb-mapei thum.jpg?Culture=en-CA&sfvrsn=f54fe0f9_2)

![Expancrete [NA]](https://cdnmedia.mapei.com/images/librariesprovider65/products-images/4_3000771-expancrete-20kg_f6c8fd7918f94633a2f246295e59e876.tmb-mapei thum.png?Culture=en-CA&sfvrsn=f5122c4_2)

Toll-free within Canada:

Technical Services at 1-800-361-9309

Customer Service at 1-800-668-1212

Copyright © 2025 MAPEI Inc. All rights reserved.

2900, avenue Francis-Hughes, Laval (Québec) H7L 3J5

Comments

Load more comments