No matter what your specification calls for as a topcoat, every installer knows the importance of ensuring it goes on a suitably flat and level surface, concrete or otherwise. This step in the process is a crucial one for interior floors, whether it’s a renovation or a new construction, and each job comes with its own unique challenges. So choosing the best self-leveling underlayment (SLU) for a given job shouldn’t be taken lightly.

No matter what your specification calls for as a topcoat, every installer knows the importance of ensuring it goes on a suitably flat and level surface, concrete or otherwise. This step in the process is a crucial one for interior floors, whether it’s a renovation or a new construction, and each job comes with its own unique challenges. So choosing the best self-leveling underlayment (SLU) for a given job shouldn’t be taken lightly.

MAPEI has been developing and perfecting such self leveling underlayment compounds for decades, and recent years have brought out self-leveling products that provide measurable benefits, like improved ease-of-use and quicker installation times.

So, what does the latest self-leveling underlayment technology have to offer?

If you have ever had a floor surface that was so far from flat, whether a high-traffic commercial floor or a residential basement floor, you had to do multiple lifts to get the entire floor surface sufficiently level, you’ll really appreciate Novoplan DPL, which can handle up to 4" (10 cm) of depth in a single pour.

If you have ever had a floor surface that was so far from flat, whether a high-traffic commercial floor or a residential basement floor, you had to do multiple lifts to get the entire floor surface sufficiently level, you’ll really appreciate Novoplan DPL, which can handle up to 4" (10 cm) of depth in a single pour.

Instead of having to make multiple applications, factoring in curing time between each lift, this easily mixed and easily placed self-leveler can be a huge time and labor saver when depth of pour is an issue. Plus, it still boasts good flow properties, and is ready for tile, stone or other floor coverings after just 24 hours.

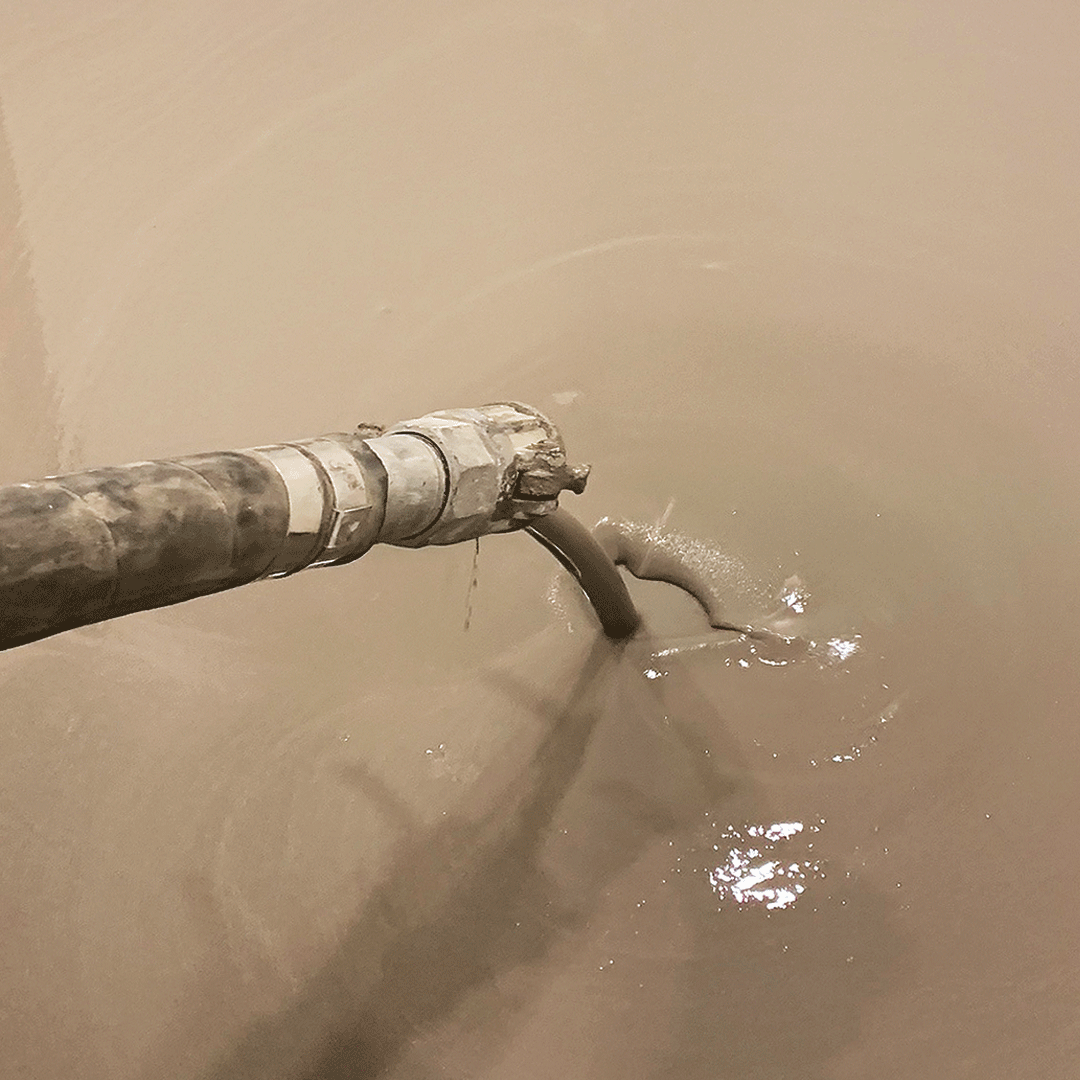

In a recent new-build hospital and cancer care center in Grande Prairie, Alberta, installers appreciated the fast-track benefit of pumpable Ultraplan M20 Plus, which is calcium aluminate-based, and rapid-setting.

It is specially formulated for the resurfacing and construction of interior horizontal surfaces as a high-compressive-strength underlayment with maximum resistance to wheel tracking and indentations, which makes it an excellent, cost-effective solution for hospitals and other institutional buildings.

Its pumpable formulation made it easy to spread evenly on winding hospital hallways with a long hose jerry-rigged on a trolley, allowing them to completely cover and level some 100,000 square feet (9 290 m²) of concrete floor on a tight schedule.

The latest innovation from MAPEI’s worldwide research laboratories, Novoplan HFL, is something we can describe basically as “flow and go.” It was developed based on direct contractor feedback, and their need to have a self-leveling compound that essentially places itself, unlike concrete, allowing virtually anyone to create a suitably smooth and level substrate for the installation of a wide variety of floor coverings.

The latest innovation from MAPEI’s worldwide research laboratories, Novoplan HFL, is something we can describe basically as “flow and go.” It was developed based on direct contractor feedback, and their need to have a self-leveling compound that essentially places itself, unlike concrete, allowing virtually anyone to create a suitably smooth and level substrate for the installation of a wide variety of floor coverings.

It’s the farthest flowing and fastest spreading self-leveling compound MAPEI has come up with to date, requiring minimal effort, and can almost be finished without the use of a gauge rake, smoother or spike-roller.

All these MAPEI self-levelers also happen to be third-party certified for low Volatile Organic Compounds (VOC) emissions. Many self-leveling underlayment manufacturers are quick to add labels like “low-VOC” or “zero-VOC” to their products without anything substantial to back the claim up – something known as “green-washing.” Of course, that does not mean they are safe or good for your health, nor does it mean there are no toxic chemicals present.

All these MAPEI self-levelers also happen to be third-party certified for low Volatile Organic Compounds (VOC) emissions. Many self-leveling underlayment manufacturers are quick to add labels like “low-VOC” or “zero-VOC” to their products without anything substantial to back the claim up – something known as “green-washing.” Of course, that does not mean they are safe or good for your health, nor does it mean there are no toxic chemicals present.

VOC content (what’s in the product) does not correlate to VOC emissions (what the product emits). Ergo: products with zero or low VOCs can still emit VOCs. To confidently select a low-VOC self-leveling product, customers should look for products that have been third-party tested and certified.

SCS Indoor Advantage Gold certifies compliance with the most rigorous indoor air quality emissions standards in North America - the California Department of Public Health (CDPH) Standard Method v1.2-2017.

These VOC-emissions certifications also contribute to green building standards and certification programs, including LEED, the WELL Building Standard and the Living Building Challenge and more.

Proper surface preparation is crucial to successfully installing self-leveling underlayments, so make sure to read all Technical Data Sheet (TDS) requirements before starting your project.

For more information about how to level a floor with self-leveling compound, or when to use self-leveling compounds, consult our reference guide: “Surface-preparation requirements for self-leveling underlayments” in the Technical documentation section of the Floor Covering Installation Systems page on MAPEI’s Website.

After surface preparation has been completed, foam tape 1/4" (6 mm) wide should be applied around the edges of the walls, columns, supports and equipment to allow for expansion and to prevent the self-leveling compound from flowing under walls. In addition, a bead of caulk along the walls will keep the self-leveler from flowing into other areas.

The use of an appropriate MAPEI primer is required. Before priming, make sure to remove all sealers and contaminants that may inhibit bond. In addition, the existing finishes should be well bonded. Priming is critical in helping the SLU to bond. When applied over porous surfaces that soak up the self-leveling compound, primers prevent uneven drying, which can cause cracks.

And if you have questions at any point, know that there are proven techniques to help installers avoid common pitfalls. The MAPEI Technical Services team is always ready to help guide you through the process every step of the way, at 1-800-361-9309.

Comments

Load more comments