When the pros in Hollywood are going to make a blockbuster movie, they don’t have their millionaire stars risk life and limb. Instead, they invest a smaller amount in a stunt double who presents far less risk in achieving the final product while wowing the audience. When dealing with immense potential liability due to the scale, cost, or technical challenges of a project, we in the manufacturing business highly recommend using a stunt double... that is, a mockup.

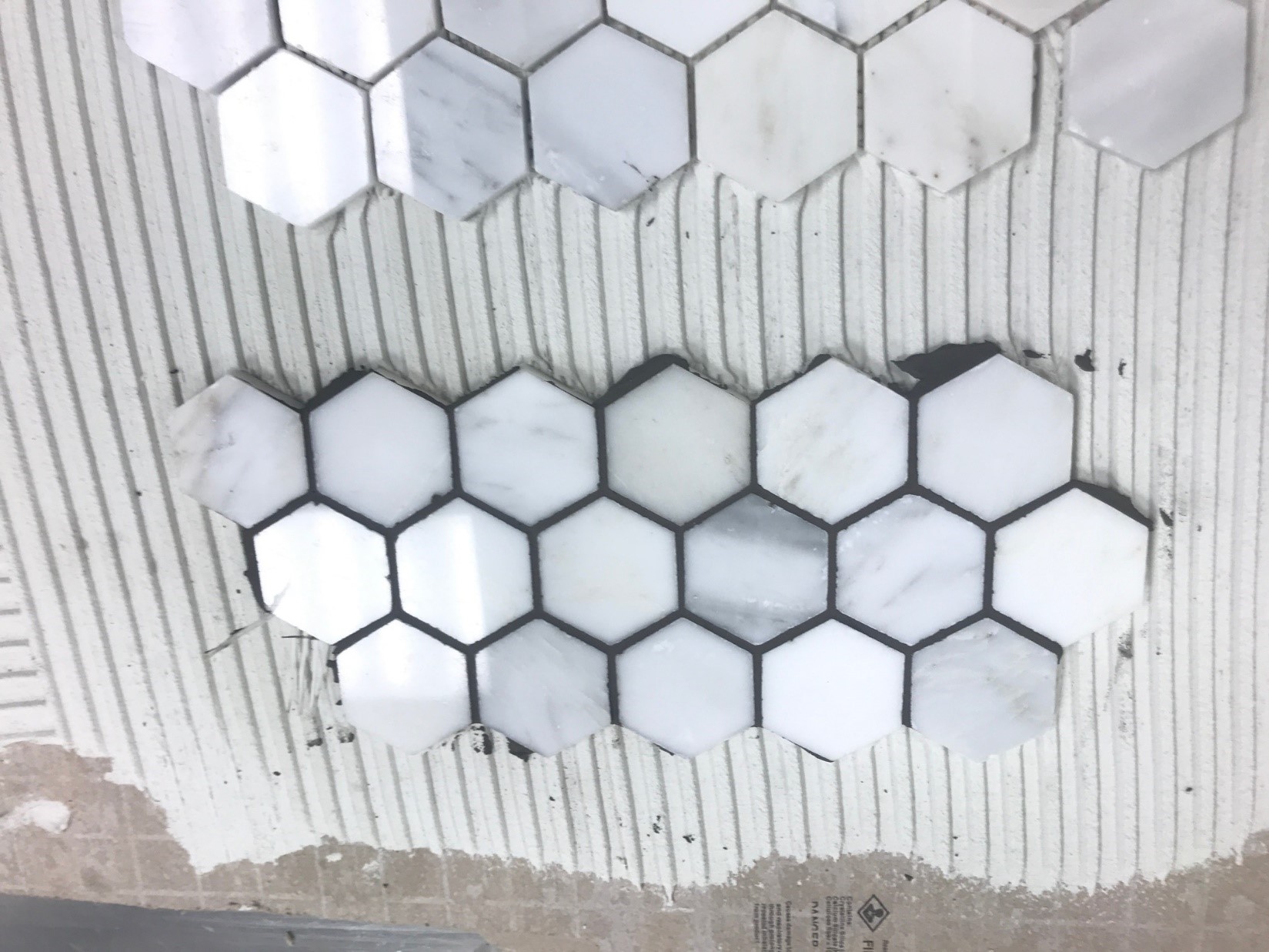

The mockup involves all of the selected installation materials and tile (or dimensional stone). This is a good time to point out that pulling from several intermixed cartons/lots of stone or tile is the best practice, when possible. The planned products are all used together on an identical-substrate sample, or they can be installed in a limited area at the actual jobsite. Some problems that present themselves shortly after a project commences will appear on a small sacrificial area instead.

It’s worth pointing out what we can evaluate by doing a mockup and what we cannot. Unfortunately, unless testing (such as the Robinson test) is conducted, a mockup is too short-lived to be an indicator of durability, or of seasonal stability for exterior projects. Changes in substrate and working environment are also variables that an installer must always watch for.

One problem that can be avoided is incompatibility with the setting mortar. Some types of natural stone will exhibit discoloration or dimensional change when in contact with water containing cement-based products. Finding this out beforehand can set you on a path toward a premium thin-set or epoxy setting mortar, depending what is needed.

Note: The aluminum straight edge touches both edges of the tile, and there is a gap under the middle. This shows that the tile has taken on a VERY subtle U-shape. Water from the thinset is what affected the product in this case.

If a mockup is properly tested for bond performance, it is also possible to ascertain whether the combination of the tile back and setting material performs adequately. Examples that I have seen where a problem relating to tile/stone could have been tested are: reinforced-tile or mosaic mounting meshes, resin backings (epoxy or urethane), tile contamination such as release agents, and friable/weak tile (slate, marble, etc.). All of these can limit bond performance.

Note: This example shows a bond strength test, using an informal, qualitative method. Since the tile came up in tiny chips instead of popping off of the thinset, we can appreciate that the tile bond is pretty good.

The substrate and preparation method can also be evaluated depending on the bond strength achieved and where separation occurs in the assembly. It’s worth being aware of a firm who operates in your area, in case a provider of bond testing is called for.

The mockup is also a good place to discover things about the relationship between the tile and the grout. Is this tile susceptible to showing a border bleeding effect (called picture-framing)? Is this tile worth treating with a pre-sealing or a pre-grout release product? Such is the case when grout is difficult to wash or easily produces a grout haze.

Note: Testing to look for any interaction between the grout and tile (haze, picture framing, staining, etc).

Where exotic natural-stone types such as Serpentine (green marble) or high-iron quartzite are being installed, a mockup is highly recommended. This is to ensure that the physical and chemical properties of the products do not react with each other. And while we are at this stage of discussing a mockup, if a sealer is to be used on the whole project, it can and should be used on the mockup.

A tile installation can immediately speak to a job well done, or it can result in a callback. Because callbacks and owner shutdowns can quickly add up, mockups are an easy way of eliminating unexpected problems. Much like using a Hollywood stunt double, a problem with a mockup can reduce the chance of a career-ending performance!

Toll-free within Canada:

Technical Services at 1-800-361-9309

Customer Service at 1-800-668-1212

Copyright © 2025 MAPEI Inc. All rights reserved.

2900, avenue Francis-Hughes, Laval (Québec) H7L 3J5

Comments

Load more comments