Today’s discussion will cover a little emblem that installers might have noticed, and would definitely do well to know what it is. With this information in hand, you as a customer will know how to compare the performance of installation materials, even if you haven’t used them before.

The badges or emblems in question look something like this:

.jpg?sfvrsn=f38eb071_0)

Firstly, and this is my personal opinion on the matter, kudos to manufacturers who bother to get their products tested and certified in accordance with International Standards Organization’s (ISO) 13007 classification. That means kudos to MAPEI, and kudos to our competitors who join us in marking products with these badges. This badge is not unlike the nutrition information labels found on food packaging. Rather than tell us specifically what ingredients are in the product, the badge tells us what the product will do for us. Instead of seeing which bag of chips has more salt or carbohydrates, it tells us which thin-set mortar has enhanced adhesion to plywood, or which has extended open time, and more.

Note: There are other performance standards for tile products such as ANSI standards, but I think that ISO 13007 does the best job of giving the most amount of information with the most intuitive and abbreviated product markings. This gives us meaningful performance information at just a glance.

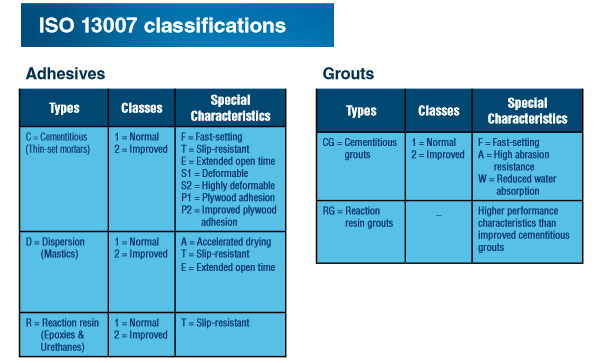

Before I get into the details, you should take note of this table, and refer back to it as needed. Pay special attention to the “Types” column. Every ISO 13007 certified product is going to have a badge that starts with its “Type”, and is followed by any code-letter that designates other features of the product. C and CG are for thin-set mortars and grouts respectively, where the C stands for cement. D is for mastics, or premixed ready-to-use adhesives, where the D stands for dispersion. R and RG are for 2-part products such as epoxy and 2-part urethane, where the R stands for reaction resin.

Product Classes – Product class relates to the adhesive or grout’s base performance. To put it plainly, Class 2 products are better than Class 1. Keep in mind, even being Class 1 tells us that a product has considerably decent performance.

Depending on project demands or jobsite environments, we would suggest different grades of products in order to meet jobsites needs. If jobsites are demanding such as exposure to high temperature change, or consistent water exposure, even exposure to frequent F/T cycles, we would recommend premium products such as Class 2 with advanced performance.

Adhesives and mortars with Class 2 performance have better bond than Class 1, and have better bond in challenging environments, including those with heat and water exposure. Cementitious grouts with Class 2 are basically more durable, stain resistant, and/or resistant to the kinds of breakage (cracking, delamination, and crumbling) that happens over the life of an installation. If a product meets Class 2 specifications as an ISO 13007 characteristic, then it is a CG2 grout.

Product Characteristics – The characteristics are most self-explanatory, but I’d be remiss if I didn’t go over these items to make sure we’re on the same page. Among the list of characteristics (or features), there are a couple that even have two tiers of performance. In the interest of not getting too bogged down in the details, just remember that a Level 2 characteristic is better performance than Level 1.

MAPEI products undergo rigorous lab testing to obtain ISO 13007 certification.

Adhesives

|

F (as in C2F) stands for fast. Fast, or rapid-setting mortars that meet ISO 13007 standards will achieve a tensile bond strength (pull test) result of at least 0.5 Megapascals (MPa*) in just 6 hours (in the ISO 13007 specified lab conditions). |

|

S1 & S2 characteristics are for thin-set mortars that have deformability, or flexibility. This feature is important wherever the installation is subjected to movement, or expansion and contraction caused by: seasonal temperature change, weather and other environmental factors that cause movement in a structure, indirect impact or vibration (such as that experienced on suspended concrete in busy commercial settings, and more).

P1 & P2 are specific to plywood. Now, plywood is typically a challenging surface to bond to. A thin-set mortar that has the P1 or P2 feature can achieve at least 0.5 or 1.0 MPa (respectively) tensile bond strength to plywood. It is far more common (and easier) for thin-set mortars to have sufficient bond strength to porous concrete, but a P-rated thin-set has enough of the good stuff to get similar tensile bond numbers to underlayment grade plywood.

A being included on a grout’s ISO 13007 label tells us that the grout is more resistant to abrasion. Rain, traffic, scrubbing, cleaning and other forces can tend to wear grout down over time. This presents itself as grout joints that don’t look as full as when they were new, and it means that it is time for a re-grout. Luckily, you can buy a CG2A grout, and it will stand up better over the years.

W indicates that a cement grout has reduced water absorption. As you might have guessed, this means that the rate and total amount of water absorbed by the grout is lower. This is a valuable feature, because so many things that are known to spill on - and stain - grout, are liquids. So, we could say the grout is less permeable. The best way to talk about this feature with cement grout, is to say “since it has reduced water absorption, there is more time for the owner or cleaner to react to a spill.” These grouts should have less severe staining than a cement grout that doesn’t have reduced water absorption, as long as an attempt to clean the mess is made within a reasonable amount of time.

RG stands for “Reactive Resin, or Epoxy and Urethane Grout.” Referring back to the table above, epoxy and urethane that meet or exceed ISO 13007 specifications do not have the performance characteristics on displayed with a class identifier (1 or 2). RG grouts are often used in the cases where special chemical resistance is required on the projects.

Note: while it is true that the products are lab tested for certification, this is the only way to make a standardized system like this, able to compare products “apples to apples” if you will. Site testing may yield slightly different results. However, the installer can be assured that ISO 13007 certified products aren’t certified with cherry-picked conditions.

I hope that you enjoyed this article on what I think is an often overlooked piece of information that says so much about a product with just a few letters and numbers. Architects, installers, and DIYers, you’re now all honorary code readers! I’ll see you here again soon with another edition of MAPEI Tech Talk. Take care and be safe out there.

Comments

Load more comments