CO2 emissions measured throughout the life cycle of products from the Zero line in 2025 using Life Cycle Assessment (LCA) methodology, verified and certified with EPDs, have been offset through the acquisition of certified carbon credits in support of forestry protection projects. A commitment to the planet, to people and to biodiversity. For more details on how emissions are calculated and on climate mitigation projects financed through certified carbon credits, click here.

The residual CO2 emissions from the products of the new Mapei ZERO line are fully offset; a commitment to quality that enables the construction and sustainable renovation of existing buildings, with an eye toward future generations, the well-being of the planet, and those who inhabit it.

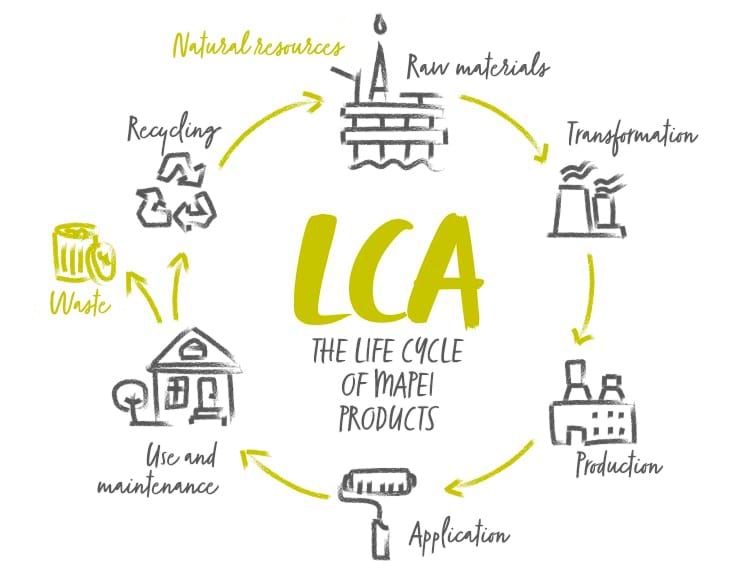

CO2 emissions from our products are expressed in kg CO2 eq/kg of product and are calculated using standardised LCA (Life Cycle Assessment) methodology. The analysis of the life cycle of a product is an evaluation of the environmental impacts the product has throughout all the various phases of its life, from cradle to grave: from extraction of the raw materials that make up the formula to their transport to the production plant, the production cycle, product packaging, waste materials, transporting the finished product to the distributor and its final disposal.

The results obtained through LCA are verified and certified by an external body with an EPD, or Environmental Product Declaration. An EPD shows the environmental impact of a product during its life cycle.

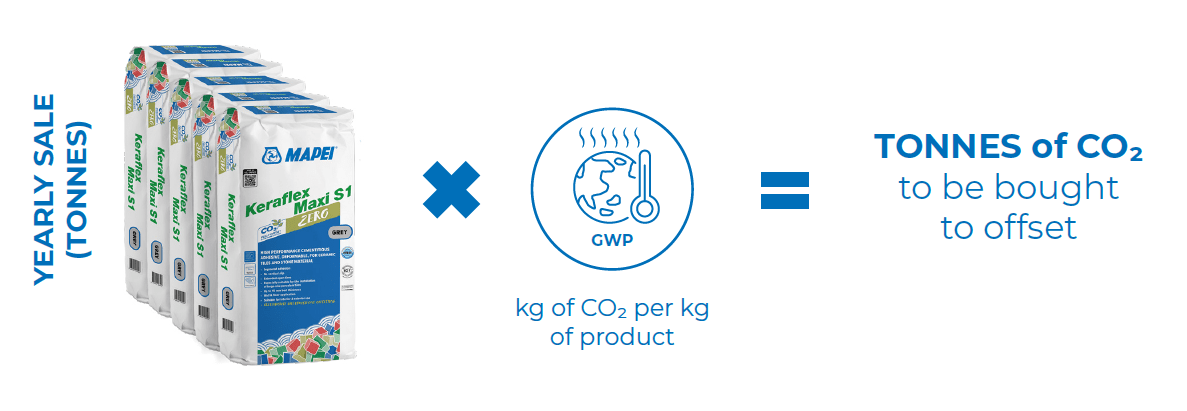

Once the amount of CO2 has been calculated and expressed in kg CO2eq/kg of product, this figure is multiplied by the amount in tonnes of product sold.

SOIL CONDITIONING

Soil conditioning with foaming agents is an extremely important operation during Earth Pressure Balance (EPB) tunnelling and is directly linked to Tunnel Boring Machine (TBM) performance. Foaming agents are mixed with the soil during EPB excavation for management of the pressure at the tunnel face, controlling the soil extraction, reducing wear on the cutting tools, and maintaining safe operations of the TBM.

The technical performance of soil conditioning products is an important consideration, but soil conditioning is not only a technical operation, because the chemicals injected during excavation encounter underground water and remain in the excavated spoil. The classification, storage and re-purposing of the excavated material depends upon the material being non-hazardous. Considering the massive volume of spoil produced during TBM excavation (~70+ tonnes/m) this requirement can represent a significant cost to the project if toxic or low biodegradable foaming agents were used.

It is vital then, that the selection of soil conditioning products be based on the combined influence of Technical Performance, Eco-Toxicity and Biodegradability.

ECO-TOXICITY

Determining the toxicity of chemical products, including foaming agents, is performed in accordance with OECD guidelines, which rank the level of risk that a chemical product poses to water and land organisms, broken into three categories:

The level of risk is determined from the results of several tests which measure the chemicals effect on various species:

BIODEGRADABILITY

Biodegradability is determined by measuring the addition of organic material added to the soil as a result of conditioning with foaming agents and the length of time that the added organic material remains in the soil (OECD 301). The two measures for making this evaluation are:

The figure below shows the rapid biodegradability of POLYFOAMER ECO 1000/PLUS (>85% at 28 days). The difference between POLYFOAMER ECO products and other foaming agents is the low quantity of organic material added to the soil at time 0. Less organic content means faster biodegrading.

POLYFOAMER ECO RANGE

The Polyfoamer Eco range are classified under the lowest level of risk to the environment “WGK1”. The range includes ECO/100, ECO/100 PLUS and ECO/1000 PLUS. These products were developed to meet a need in the tunnelling industry for foaming agents that could satisfy the vital functions for successful EPB tunnelling, without negatively impacting the environment.

Over recent years since the introduction of ECO/100, POLYFOAMER ECO foaming agents have been used on 7 successful EPB projects that excavated more than 35 km of tunnel, including St Lucia, the words largest EPB to date.

The advantage of using Mapei’s Polyfoamer Eco products compared to traditional foaming agents, is their ability to have minimal environmental impact, whist maintaining optimum tunnelling performance. The key differences are:

Polyfoamer Eco Foaming agents combine the highest technical performance with the lowest eco-toxicity and rapid biodegradability, for sustainable soil conditioning.

Luke Foyster

Technical Engineer

Underground Technology Team

Mapei Australia