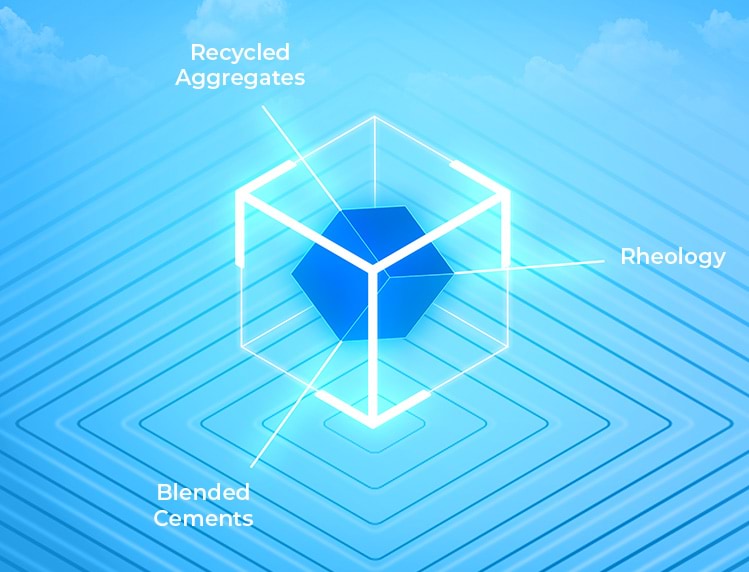

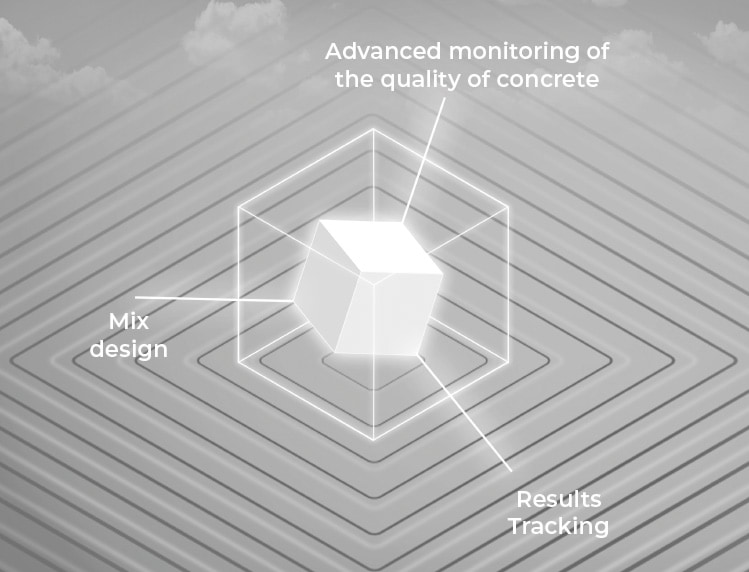

Thanks to the use of propriety technology based on nano-compounds of silicate hydrates, our patent pending system, CUBE represent the fundamental cornerstones of the next generation of admixtures for the new cements with reduced

clinker content

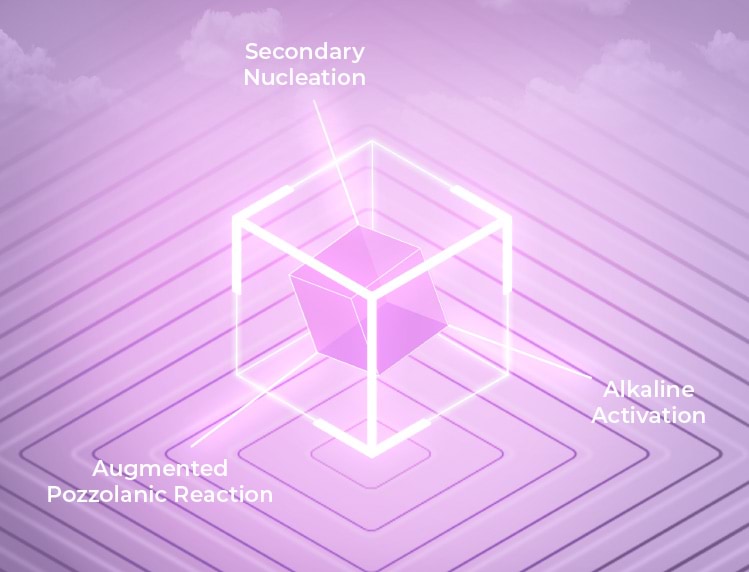

Secondary Nucleation (SN)

The addition of

nano-composite silicate hydrates produces hydration reactions more rapidly and diffusely in the cement paste.

Augmented Pozzolanic Reaction (APO)

The combination of

nano-compounds of silicate hydrates with retarding accelerators produces a more

powerful pozzolanic reaction,

thereby enabling faster development of mechanical strength after both short and long curing cycles.

Alkaline Activation (AA)

The new

hybrid cements have a

smaller carbon footprint and combine the properties of OPC with the properties of alkaline activation materials.

Development of the mechanical strength of hybrid cements is promoted by the alkaline activation of their components.

| MAPECUBE 1 |

Strength enhancer after short curing cycles |

| MAPECUBE 2 |

Strength enhancer specific for cements with limestone |

| MAPECUBE 4 |

Strength enhancer specific for cements with fly ash or slag |

| MAPECUBE 60 |

Strength enhancer for all cements and SCM |

| MAPECUBE 60W |

Strength enhancer for all cements and SCM |